So I’m going to try a new thing: AI assisted posting. It’s been like 3 years since I wrote anything. Better late than never? You’ll see that I will tend to break things into sections – the human part and the cyborg part. Let’s see if this leads anywhere. Can I connect two MPPT Controllers […]

Solar angle over peak solar input

I think this graph is neat, because it shows a long history of solar angle as the year marches on. As you can tell, we’re not driving a lot right now, though. If we were moving in latitude, you’d see the solar angle deviate from the seasonal curve. If we were moving in longitude, you’d […]

Deep battery discharge – hot and cloudy.

I thought this graph might be of interest to those who want to see what happens when you run a large Nissan leaf pack down to zero state of charge. (SOC) It’s been consistently 90 degrees during the day and still about 75-80 at night, the last few days have been cloudy, I left the […]

Where did you get that faucet?

I’ve had a bunch of people ask me where we got the faucet in our bus kitchen. We actually were inspired by some friends who are on Instagram by the name of @nomadicmillers. GAPPO Gold Kitchen Faucet Pull Out Kitchen Faucet Dual Handle 3 in 1 High Arc Water Filter Purifier Faucets Golden Whew! Thats […]

Home Assistant Conference

Today I will be presenting a short talk about our bus’s Home Assistant development. Here’s a link to the youtube live stream: https://www.home-assistant.io/conference/

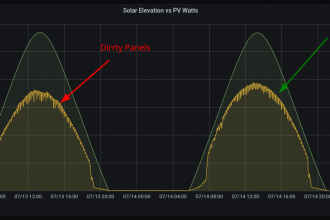

Clean vs Dirty Solar Panels

I washed my solar panels for the first time in a few months. Here’s the difference on two nearly identical solar days.

Pantry and Fridge Latch System

Several people have asked how we keep the fridge doors latched. Basically, we use a door lock latch, like this one. (Click for details!) We started with adhesive child lock latches on the fridge, but it was weak and would pop open occasionally for a big surprise when driving – not the safest. The inspiration […]

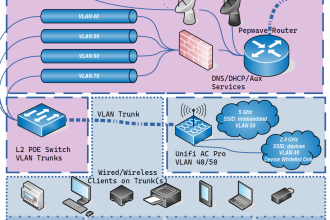

Internet and Network Overview

Internet was one of the most challenging technical implementations I had to solve on the bus. For me, it was more difficult than building the battery and energy systems, or the roof raise. Here is a brief tale of my journey. While building the bus, I placed a spare wireless router in it that just […]

Skooliepalooza 2020 Solar Discussion

Here’s the slide deck for the presentation. I’ll be presenting at 3:00 PM MST on January 26, 2020 right about here: